The license plate recognition weighing and loading integrated control system is a comprehensive integrated software system that integrates the license plate recognition access system, the weighing system, the loading control system, and the loading and ordering payment system.

Project Advantages:

✅Highly Automated Operation:Combines multiple subsystems into one intelligent platform, minimizing manual intervention.

✅Enhanced Efficiency:Greatly improves the overall operational speed and accuracy of loading and weighing.

✅Real-Time Data Management:Instant data collection and synchronization with the central control system.

✅Accurate Billing & Transparency:Automatic recording of each loading transaction ensures fair and precise charging.

✅Remote Monitoring & Control:The main control room can oversee and operate all lanes, reducing labor and error.

✅Optimized Resource Utilization:Improves coordination between loading, weighing, and transportation processes.

✅Scalable & Customizable:Flexible system architecture for future expansion or adaptation to new materials or processes.

Project Description:

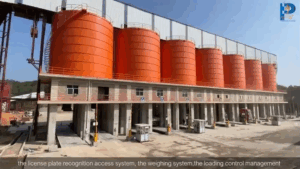

This project was implemented for a construction material supplier specializing in stone production. The client needed a comprehensive, automated management system to handle multiple processes — including vehicle entry, license plate recognition, weighing, load control, and order-based payment.

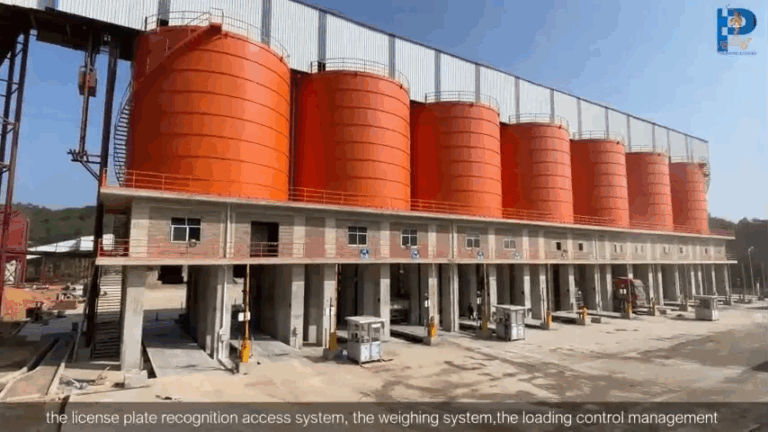

The project involves 14 lanes, each corresponding to a different stone specification. Vehicles are automatically guided to the correct loading lane based on the order registered at entry. From the moment raw stones are crushed to when trucks are loaded, weighed, and billed, every step is precisely monitored and controlled by the system.

Through the seamless integration of license plate recognition, weighbridge operation, and automated loading management, the system ensures efficient, transparent, and traceable loading operations throughout the factory.

Project Requirements:

The client required a fully automated and integrated solution capable of:

- Kusimamia vehicle entry and exitwith license plate recognition.

- Connecting weighing control, loading controlya order charging systems.

- Automatically identifying stone specifications and directing vehicles to designated loading lanes.

- Recording and accumulating loading datakwa wakati halisi.

- Kutoa remote monitoring and centralized controlfor all 14 lanes.

- Generating billing data automaticallyfor monthly settlement with the construction company.

Solutions We Provide for Customers:

TGW delivered a comprehensive intelligent automation system that combines:

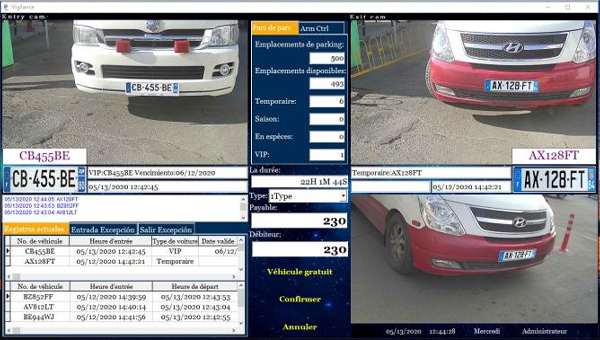

- License Plate Recognition Access Control:Enables automatic vehicle identification and gate management.

- Weighbridge Integration:Accurately measures vehicle load before and after loading, with real-time data feedback.

- Loading Control System:Starts and stops the loading process automatically once the target weight is reached.

- Order Payment System:Links loading data with the driver’s ID card and payment records for transparent billing.

- Centralized Monitoring Platform:The main control room displays the operation status of all 14 lanes, allowing remote supervision and manual intervention if necessary.

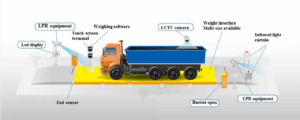

Each lane is equipped with:

1 barrier gate, 1 medium-distance reader, 1 LED display, 2 CCTV cameras, 1 alarm light, and 3 infrared sensors, integrated with the weighbridge and the loading system for seamless operation.

For more details about the solutions, please contact us via email: info@sztigerwong.com